Gamma Irradiation is the best choice not only for the manufacturers to process their products but for the end users who are satisfied with the products which are processed with Gamma Irradiation. This is the most trustable and effective advertisement for promoting the products. The high penetration allows materials to be sterilized in bulk.įor the manufacturers of the medical facilities and the end users, labeling “Gamma irradiation” on the product packages means the reliable and effective way for sterilization. Gamma Rays penetrate both thick and thin objects, as well as dense materials.

This allows the product to be used immediately after sterilization. Products exposed to these gamma rays acquire no radioactivity. This low-temperature process can sterilize a package at under 100° F (38° C). The product being sterilized is placed near the radiation source until the required dose is absorbed. The simplicity and speed of gamma radiation sterilization is a great part of its appeal for sterilizing health care products, components, and packaging. It is absolutely environment-friendly process. Gamma irradiation is the most efficient method of sterilization which require only one parameter mainly “Time of exposure” to be monitored. It is difficult to dispose of spent Cobalt-60 because it has a half life of 5.3 years. Most importantly, there is no residual radioactivity after irradiation while the other method of sterilization i.e using Ethylene oxide (ETO) requires control of temperature, time of exposure, pressure, vacuum, humidity, quarantine after the process apart from leaving residual toxic substance on the products. Consequently, there is no heat stress and condensate drainage or out gassing is not required. It can be applied under safe, well-defined, and controlled operating parameters, and is not a heat- or moisture generating process.

Gamma irradiation provides a number of benefits in cost and sterility assurance. The absorbed dose is measured in units called kiloGrays (kGy). Cobalt-60 Gamma radiation typically has energy of about 1.2 MV, D-max being 0.5 cm. Gamma rays pass readily through any material and kill bacteria by breaking the covalent bonds of bacterial DNA. The primary industrial sources of gamma rays are radionuclide elements such as Cobalt 60, which emit gamma rays during radioactive decay. The other two types of natural radioactivity are alpha and beta radiation, which are in the form of particles. Gamma rays are electromagnetic radiation, like X-rays.

or death.Sterilisation of medical products is most critical for controlling microbial contamination.

#Disadvantages of using cobalt 60 skin#

Mishandling of a large industrial source of Co-60 could result in an external exposure large enough to cause skin burns, acute radiation sickness radiation sicknessA serious illness that can happen when a person is exposed to very high levels of radiation, usually over a short period of time. Cobalt-60 absorbed by the liver, kidneys, or bone tissue can cause cancer from internal exposure to gamma radiation.

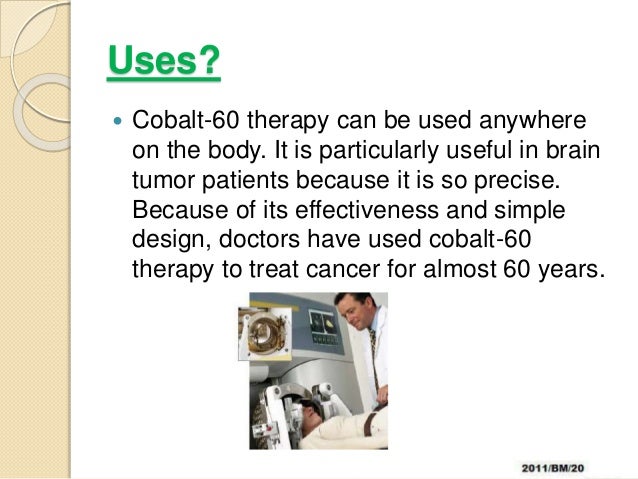

Most Co-60 that is ingested is excreted in feces however, a small amount is absorbed by the liver, kidneys and bones. Cobalt and Healthīecause it decays by gamma radiation, external exposure to Co-60 can increase cancer risk. Such exposures are carefully controlled to avoid adverse health impacts and to maximize the benefits of medical care. Most exposure to Co-60 takes place intentionally during medical tests and treatments. Though relatively rare, exposure has also occurred by accidental mishandling of a source at a metal recycling facility or steel mill. Accidental exposures may occur as the result of loss or improper disposal of medical and industrial radiation sources. It is also used for radiation therapy in hospitals. Cobalt-60 is used as a radiation source in many common industrial applications, such as in leveling devices and thickness gauges.

0 kommentar(er)

0 kommentar(er)